Building 101: A Look at Service Panels and Their Purpose

Posted by Best Access Doors on 15th Mar 2018

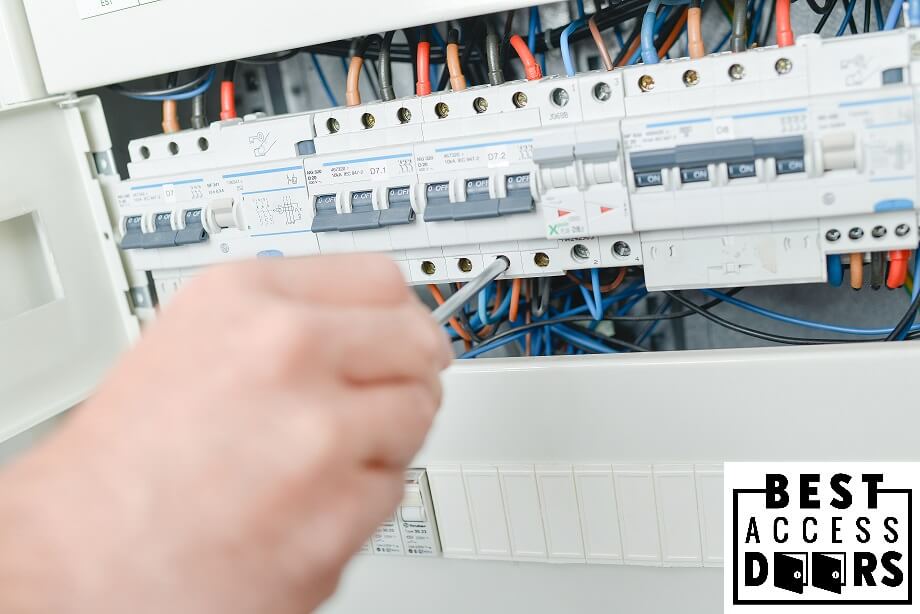

At the heart of every building's electrical system is a service panel. These components control power distribution, protect circuits from overload, and help teams isolate issues quickly.

For contractors, engineers, and facility managers, keeping these panels accessible is just as important as understanding how they function. Maintenance and repair of service panels can become difficult without proper access points.

This can lead to downtime, high repair costs, and even pose safety and compliance risks. This article breaks down what service panels do, how they've evolved, and why access doors play an important role in protecting them without limiting serviceability.

What Is a Service Panel and How Does It Work?

A service panel is the central control hub that receives incoming power and routes it to individual circuits through protective breakers. Think of it as the command center that every circuit in a building traces back to.

In large buildings like hospitals or manufacturing plants, subpanels help divide and manage loads more efficiently. During outages, overloads, or breaker trips, professionals go straight to the panel for diagnosis and reset. This makes proper access and code adherence essential for safety and response speed.

Engineers and maintenance teams depend on well-installed panels to prevent downtime, meet NFPA 70 standards, and streamline inspection.

Even minor issues can escalate into safety incidents or operational delays when service panels are inaccessible.

Ready to protect your building in an emergency? Browse our access solutions today and save time and money on building inspections.

What Factors Should Contractors Consider When Specifying a Service Panel Location?

A service panel is only as effective as its placement, which must support safety, accessibility, and code compliance from day one. Installing a panel in the wrong location can result in failed inspections, added labor costs, and difficult maintenance down the line.

Key considerations include:

- NEC Clearance Requirements: The National Electrical Code (NEC) mandates that technicians have unobstructed access to working space in front of electrical panels, typically 30 inches wide and 36 inches deep.

- Safety Zones and Environmental Hazards: Avoid high-moisture zones (e.g., near washdown areas), high-traffic corridors, or locations where accidental impact is likely. Placing panels too close to mechanical hazards in industrial environments may create OSHA concerns.

- Coordination with Other Building Systems: Electrical panel placement should be coordinated early with plumbing, HVAC, fire protection, and utility routing to avoid conflicts and ensure clean layout planning.

- Future Expansion Needs: Panels with no surrounding space for upgrades may limit load expansion or complicate future retrofits.

When these factors are overlooked, contractors risk creating a service bottleneck rather than a central hub.

Planning for proper access from the start makes it easier to integrate protective access doors later without requiring relocation or rework. Request a quote today and simplify maintenance from the outset.

What Problems Do Contractors Have With Inaccessible or Exposed Panels?

Poorly placed service panels can create safety, compliance, and liability issues. Common challenges include:

- Violations of NEC working clearance rules, OSHA safety issues linked to restricted access, or failed approval due to unlabeled or obstructed panels.

- Technicians may struggle to reach the panel during emergencies. Overcrowded mechanical rooms make troubleshooting difficult.

- Exposed panels or poor locking provisions invite vandalism or accidental breaker trips.

- Panels can suffer impact damage in high-traffic zones. Moisture, dust, or debris can also increase the risk of electrical faults.

- Visible industrial panels may disrupt clean architectural finishes. Property owners often request retrofitted enclosures or concealment solutions

These issues highlight why panel installation must be paired with intentional access planning. The right access door helps contractors conceal panels without compromising code-required accessibility, enabling protection, security, and visual integration in one step.

What Are the Best Practices for Managing Service Panels Professionally?

Effective panel management starts with maintaining clear accessibility, accurate labeling, and adherence to NEC clearance requirements.

- Circuits should be identified per NEC Article 408 to support future upgrades and fast troubleshooting.

- Routine inspections help detect overheating, loose connections, corrosion, or breaker fatigue before failures occur.

- Load calculations must be checked regularly to prevent overcapacity issues and allow for expansion.

- To improve safety in high-traffic or controlled environments, contractors often specify lockable covers or access doors that comply with OSHA safety standards and maintenance protocols.

Which Access Solutions Are Best for Electrical Panel Installations?

Electrical panel installations benefit most from access doors that combine safety compliance, secure access, and clean aesthetics.

At Best Access Doors, contractors commonly choose from the following electrical-friendly access solutions:

Flush Steel Access Doors

Perfect for commercial utility rooms, corridors, and multi-unit electrical zones, these doors offer:

- Strong steel construction for long-term durability.

- Low-profile, flush finish ideal for clean drywall or masonry installs.

- Optional key or cam locks to help restrict access to authorized personnel only.

They're best for general electrical panels that require frequent inspection and maintenance in non-rated areas.

Fire-Rated Access Doors

In buildings with electrical panels in fire-rated walls or corridors, fire-rated access doors like the BA-FRI Fire Rated Insulated Access Panel ensure compliance with fire performance codes. They feature:

- Durable steel construction

- UL-listed fire ratings

- Intumescent seals that expand when exposed to heat, helping contain flames and smoke

- Insulated core options help maintain wall assembly integrity.

They're best for electrical service rooms, corridor panel enclosures, and mechanical spaces that fall under IBC/UL fire code requirements.

Insulated & Airtight Access Doors

Certain electrical installations, especially those within conditioned environments or airtight enclosures, require protection from moisture, dust, or temperature fluctuations.

Foam-insulated or gasketed doors support environmental control. It also helps safeguard sensitive digital electrical controls and breakers, preventing condensation and corrosion risks.

Insulated or airtight panels are best for electrical rooms in hospitals, data centers, high-humidity zones, or energy-efficient buildings.

Security Access Doors

Electrical systems in government, critical infrastructure, or industrial environments may require heightened security.

Tamper-proof locks and reinforced security panels meet security standards for restricted-area equipment access.

Such panels are best for secured zones such as airports, correctional facilities, data hubs, and water treatment plants.

Custom-Sized and Finish-Compatible Solutions

Electrical panel locations vary in dimension based on breaker count and conduit routing. In retrofit scenarios, precise sizing is crucial.

Custom sizes ensure proper alignment with panel frame dimensions. Finish options (white powder coat, stainless steel, or paint-ready) support architectural integration. Optional recessed panels allow for flush finishes in architectural spaces.

High-visibility commercial interiors, retrofits, and electrical distribution zones with tight clearance benefit the most from such panels.

Frequently Asked Questions About Service Panels

1. What is a service panel in a building, and what does it do?

A service panel is the central hub of a building's electrical system. It receives power from the utility source and distributes it to individual circuits via breakers. It helps protect against overloads, isolate faults, and ensures safe power distribution throughout the structure.

2. Where should a service panel be installed according to code?

According to the NEC, a service panel must be installed in a dry, easily accessible location with a minimum working clearance of 30 inches wide, 36 inches deep, and 6.5 feet high. Placement should avoid high-moisture zones, mechanical obstructions, and impact-prone areas.

3. Why is accessibility important for electrical service panels?

Accessible service panels allow quick troubleshooting, breaker resets, and compliance with NEC and OSHA safety standards. When panels are blocked or hidden without access doors, emergency response is delayed, repair costs rise, and inspections can fail due to insufficient working clearance.

4. What are the best access doors for electrical panel installations?

The best access doors for electrical panels include flush steel doors for general use, fire-rated models for code-compliant walls, insulated access doors for moisture-sensitive environments, high-security doors for restricted zones, and custom-sized recessed panels for architectural integration and retrofit projects.

5. How do access doors improve safety and compliance for service panels?

Access doors protect electrical panels from impact, vandalism, moisture, and environmental hazards while maintaining code-required accessibility. Lockable, fire-rated, or insulated access panels provide secure entry for technicians, helping contractors meet NEC, IBC, and OSHA standards during inspections and maintenance cycles.

Conclusion

Electrical panel installations benefit most from access doors that combine durability, code alignment, ease of use, and finish compatibility.

At Best Access Doors, we offer contractor-trusted access panels designed for commercial and industrial environments requiring frequent inspection, security, and long-term performance.

Whether you're working on a retrofit, utility room, mechanical enclosure, or multi-zone power distribution project, we provide customizable options to meet accessibility and design goals.

Contact us today for a consultation and find out how our electrical-ready access panels fit your next project. Call +1-888-327-5471.

Share our story - the 2025 version is available

Feedback

Feedback