Building Safer with Fire-Resistant Cables: What Codes Don’t Tell You

Posted by Best Access Doors on 6th Feb 2026

Meeting electrical and building codes is the starting point for fire protection, not the end goal. Codes establish minimum requirements, but real-world fire performance depends on how materials behave once systems interact under stress.

Fire-resistant cables play a key role in maintaining circuit integrity during a fire, especially for life-safety and critical systems. However, their performance in an actual building fire is influenced by factors that standard tests do not fully address. Cable selection, installation methods, and how cables interact with surrounding passive fire protection systems all affect outcomes.

In this article, we’ll discuss where standard testing falls short and why a system-level approach matters in commercial construction.

Understanding the Limits of Standard Fire Tests

Most fire codes reference standardized cable tests such as IEC 60331, UL 2196, and BS 6387. These tests are useful, but they are controlled scenarios. Typically, a single cable is mounted in open air and exposed to a defined flame and temperature curve. That setup is very different from how cables are installed on site.

In commercial buildings, cables are usually bundled, run through trays, enclosed in conduits, or stacked in vertical risers. These configurations trap heat and can accelerate fire spread along cable routes. The ‘cable train’ effect allows fire to move quickly through multiple fuel paths, even when individual cables meet test requirements.

Another gap is smoke and gas performance. Flame resistance alone does not address smoke density or toxicity, which are often the greater life-safety hazards during a fire. For this reason, many commercial projects specify additional performance criteria such as Low Smoke Zero Halogen (LSZH) jackets and enhanced flame spread ratings like IEC 60332-3 Category A.

Designers and specifiers should treat test compliance as a baseline and assess whether higher-performance cables are needed based on occupancy, risk profile, and system criticality.

A System View of Fire Protection

Fire protection works as a system. Cables, walls, floors, firestopping, and access points all contribute to how fire and smoke are contained.

One of the most important principles is compartmentation. Fire-rated walls, floors, and shafts are designed to hold fire in place for a set period. That protection only works if every penetration through those assemblies is properly detailed and maintained.

Cables frequently pass through rated assemblies, which means the surrounding components matter just as much as the cable itself.

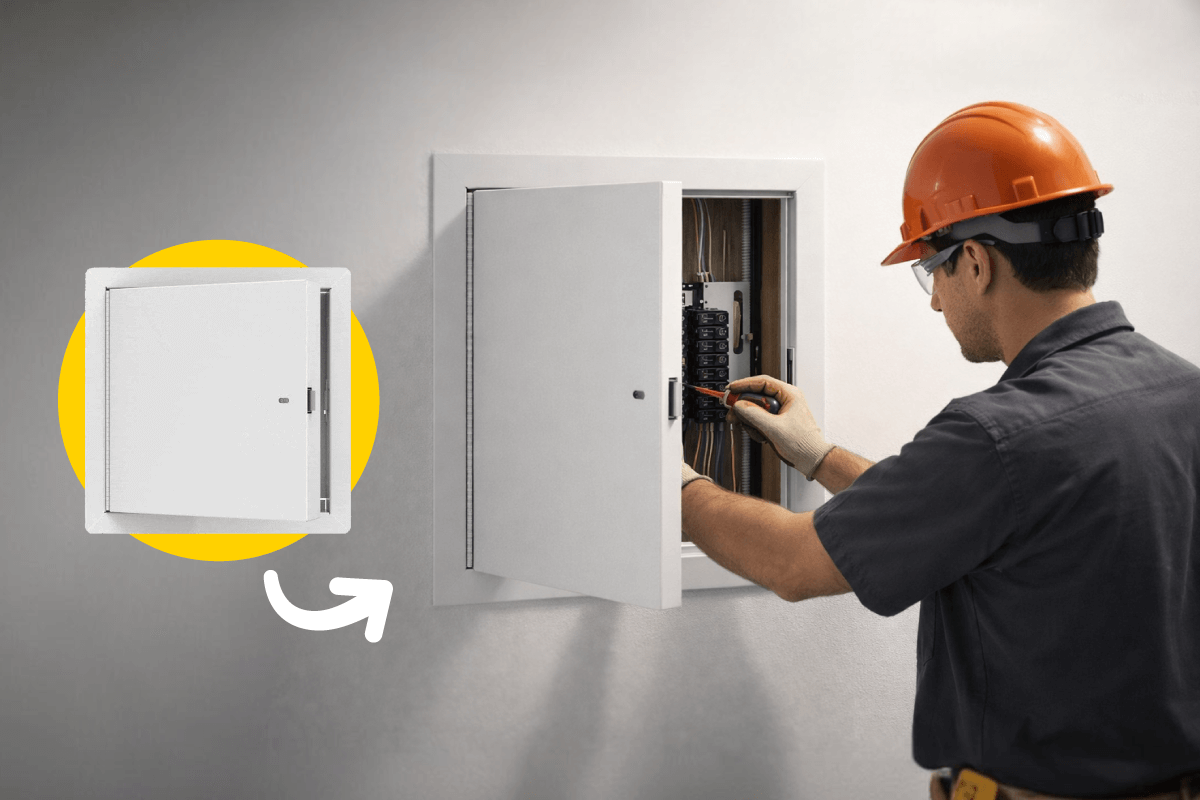

Fire-Rated Access Doors: Supporting Compartmentation

Electrical systems require access for inspection and maintenance. Panels, junction boxes, and cable trays are often located inside fire-rated walls or shafts, which makes access doors unavoidable.

A common mistake is installing a standard, non-rated access door in a fire-rated wall. That opening weakens the entire assembly and creates a path for heat, smoke, and flames to escape during a fire.

Fire-rated access doors help maintain the integrity of rated assemblies. They are tested as complete units (door leaf, frame, hardware, and seals) to match the fire-resistance rating of the surrounding wall or ceiling.

It is important to be clear about their role. Fire-rated access doors do not make a building fire-safe. They do not stop fires. They help slow the spread of fire and smoke, buying time for evacuation and emergency response. Used correctly, they support compartmentation rather than undermine it.

When access doors are required in rated assemblies, selecting properly tested fire-rated models is part of responsible system design, not an optional upgrade.

Coordination and Installation Matter

Even the right products can fail if they are poorly installed or mis-specified.

Clear specifications are essential. Fire ratings for walls and shafts must be communicated across design and construction teams. Any access door installed within a rated assembly should be specified with a matching fire-resistance rating from a certified manufacturer.

Installation details are equally critical. Fire-rated access doors must be installed exactly as tested, including correct framing methods and intumescent seals. These seals expand under heat to close gaps and limit smoke and flame passage. Cable penetrations must also be properly fire stopped using listed systems.

Inspection and maintenance should not be overlooked. Fire-rated access doors must close and latch fully, seals must remain intact, and no field modifications should compromise the tested assembly.

Moving Beyond Checklist Compliance

Effective fire protection is not about checking boxes. It is about understanding how components work together under real conditions.

That means selecting fire-resistant cables with appropriate performance characteristics, designing cable routes that limit fire spread, and ensuring that penetrations and access points do not weaken compartmentation. Fire-rated access doors support this strategy by helping maintain rated barriers, not by claiming to eliminate fire risk.

For professionals looking to deepen their technical knowledge, resources on understanding cables specifications and fire safety can help inform better design decisions across commercial projects.

When systems are designed, specified, and installed as a whole, buildings are not just code-compliant. They perform more reliably when it matters most.

Share our story - the 2025 version is available

Feedback

Feedback