How To Avoid Rework From the Start: Top Spec Tips for Complex Installs

Posted by Best Access Doors on 7th Nov 2025

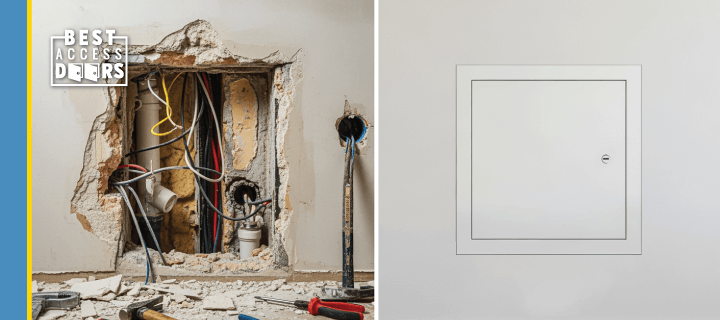

Selecting universal access doors, verifying assemblies early, and coordinating between trades prevent costly rework. Rework happens when specifications aren’t aligned with real-world installations.

Contractors lose time and margins when access panels don’t match openings, clash with drywall or ceiling assemblies, or fail inspections. In fact, data shows that rework costs can amount to more than 11% of total project costs in the construction industry.

The simplest way to stay ahead is to standardize around adaptable models like the BA-ED-2002, designed for multi-trade coordination and easy installation.

Why Does Rework Happen on Complex Installs?

Rework occurs when access doors don’t match the construction environment, surface type, or rough opening. This is often due to unclear specs, lack of coordination, or assumptions made before field verification.

Unclear Specs

Unclear specifications leave room for interpretation, often leading different trades to make assumptions.

For instance, when the spec only states “provide access panel,” without clarifying whether it's recessed or needs specific locking features, every team may move forward based on their expectations.

Other specifications that need to be clarified upfront include the design, specific equipment clearance, drywall thickness, etc. Mistakes widen with each installation stage when the wrong spec interpretation is acted on.

Poor Coordination Between Trades

In multi-trade environments, coordination is important to keep everyone on the same page. Statistics show that miscommunication and poor project data are responsible for 52% of rework in construction projects.

Take this scenario, for instance. The framing crew creates a standard 12" x 12" opening, assuming a basic wall access door will be used. However, the HVAC team installs ductwork that requires a larger clear opening for future servicing, something that wasn't clarified up front. Then the drywall team closes the wall before the actual panel model is confirmed, only to find later that the specified access door needs a deeper frame and wider clearance.

The result? A full rework of the opening that leads to more labor expenses and more time wasted on site. Contractors can avoid such instances by coordinating better between teams.

Lack of Verification

A lack of proper verification can also cause budget and timeline constraints, whether during submittals or when ordering access doors from suppliers.

For instance, an access panel for walls can be ordered for ceilings, or a contractor may assume one model fits all assembly types without checking compatibility.

When such assumptions fail in the field, installation must be redone. Inspections then get delayed, and costs escalate.

Fast-track builds worsen the issue. When under time pressure, contractors may rely on “standard panels” to keep up with timelines. In such instances, they may end up with models that aren't fire-rated for assemblies, lack the right latch type, etc. These could all result in delays, rework, or failed inspections.

Reduce errors and simplify installation with access doors built to meet multiple site requirements. Explore our high-performance, general-purpose access solutions.

How Do Specification Mistakes Impact Project Timelines?

Spec errors cause rework that delays inspections, holds back dependent trades, and force reordering cycles that can delay progress for days or weeks.

Once a panel doesn’t align with the rough opening, drywallers must reopen sections, patch surfaces, and repaint. If inspections fail due to incorrect fit or non-compliant materials, timelines extend further.

Worse, incorrect models often cause delivery delays. Replacements aren’t always stocked, especially for ceiling-rated or special-latch units.

The wrong panel finishes also lead to aesthetic inconsistencies that owners flag late in the process, resulting in last-minute chaos.

Which Installation Tips Prevent Mismatched Openings?

Field verification, rough opening checks, and specifying universal access panels are the fastest ways to prevent misalignment and rework.

Here are installation best practices that prevent costly corrections later:

- Confirm assembly type early. Know whether the opening goes into gypsum board, masonry, or grid systems.

- Verify rated vs. non-rated needs. Specifying a non-rated panel in a rated assembly causes instant rejection during inspections.

- Use submittal drawings. Manufacturer details can help set exact rough openings before framing closes.

- Use universal-fit models. Specifying a universal fit that can be used across multiple trades, like the BA-ED-2002, reduces framing adjustments. It also eliminates variations that lead to misorders or misfits. Tracking multiple panel types, finishes, latch types, etc, leaves room for mistakes.

Ready to prevent guesswork and mismatched openings before they happen? Request a quote and standardize installation details across trades with a universal, field-ready solution.

How Does the BA-ED-2002 Help Avoid Rework in Multi-Trade Projects?

The BA-ED-2002 Universal Economy Flush Metal Access Door stands out because it’s designed as a universal access door that installs easily in both wall and ceiling assemblies, minimizing trade conflicts and rework.

Here’s how its features translate into real-world project value:

| Features | Benefits on Site |

|---|---|

| Universal wall and ceiling compatibility |

Fewer SKUs Easier submittals No confusion |

|

Durable steel construction |

Prevents damage during installation or inspection cycles |

|

Prime-coated, paint-ready steel |

Blends into drywall or acoustical ceilings without rework |

|

Economy pricing |

Ideal for cost-sensitive large-scale projects Cost-effective without compromising quality |

|

Screwdriver-operated latch |

Reduces wasted time looking for specialized opening tools |

|

Flush mounting design and concealed hinge |

Delivers clean, inspection-ready finishes |

By allowing drywall contractors and ceiling installers to work from the same spec reference, the BA-ED-2002 improves coordination. No one needs to pause for clarification or request new hardware options mid-installation.

That’s especially useful during project turnovers or large facility rollouts, where consistent standardization drives labor savings and reduces costly last-minute fixes.

Frequently Asked Questions About Universal Access Doors

1. What causes rework during access door installation in commercial projects?

Rework happens when access doors don’t match the wall or ceiling assembly, are incorrectly sized, or fail inspection due to unclear specs. Without field verification, trades make assumptions that lead to misfits, deeper framing adjustments, and reopening finished drywall or ceilings.

2. How can universal access doors reduce rework and installation errors?

Universal access doors fit both wall and ceiling assemblies, reducing guesswork and eliminating the need for multiple models. This simplifies trade coordination, prevents mismatched openings, and speeds up inspection readiness.

3. What installation best practices help prevent mismatched rough openings?

The best way to prevent mismatched openings is to verify assembly type, confirm rated vs. non-rated requirements, and use submittal drawings to set rough opening dimensions. Universal-fit models help align installation steps across drywall, ceiling, and mechanical trades.

4. Why are specification mistakes costly in fast-track construction projects?

Spec errors cause rework, inspection failures, and delivery delays for replacement panels. This stalls multiple trades, extends timelines, and increases labor costs due to reopening finishes or reordering delays in fast-track projects.

5. What should contractors look for when choosing an economy flush access panel?

Contractors should look for universal compatibility, easy mounting, code-readiness, and a durable, pre-finished design. A model like the BA-ED-2002 supports wall and ceiling installs, helping simplify specs, minimize trade conflicts, and improve installation efficiency.

Wrapping Up

Preventing rework begins with smarter specification choices and using field-ready universal access doors. When contractors rely on versatile flush access panels like the BA-ED-2002, they cut down on installation guesswork, reduce trade conflicts, and move projects faster through inspections.

Consistent, code-ready choices create predictable workflows, minimize misorders, and protect profit margins.

Running a fast-track commercial project? Standardize your specs now and avoid costly rework later. Talk to our team for versatile, inspection-ready access solutions. Call +1-888-327-5471 today.

Share our story - the 2025 version is available

Feedback

Feedback