Which Access Panels Work Across Roof, Wall, and Floor Installs Without Risk?

Posted by Best Access Doors on 24th Oct 2025

No single access panel is universally safe for installation across all roofs, walls, and floors. Each surface requires a purpose-built access door to ensure sealing, safety, and long-term durability. Pick the wrong model and you will suffer from leaks, air infiltration, tripping hazards, or early corrosion—problems that affect performance and compliance.

That's why construction professionals rely on multi-surface access doors like the BA-UHF-G for airtight wall and ceiling installations and the BA-RFD for heavy-duty, slip-resistant floor access. Using them together delivers a cohesive look and consistent performance without compromising safety or compliance.

Why Should You Match Access Panels to Each Installation Surface?

You should always match access panels to each installation surface because every area—roof, wall, or floor—has different structural, load, and sealing requirements. Using the same panel everywhere may seem efficient, but it can lead to leaks, air infiltration, or compliance issues that cost more to fix later.

Address Different Functional Requirements

Each installation surface simply doesn't experience the same conditions. Roofs deal with rain, sunlight, and temperature fluctuations, so they need weather-sealed or thermally broken access doors to prevent leaks. Walls and ceilings work best with concealed-flange, gasketed models that stay flush and airtight for a clean, professional look.

Meanwhile, floors require heavy-duty, load-rated, slip-resistant hatches that handle constant foot and equipment traffic without warping or damaging.

Prevent Costly Rework and Inspection Delays

Installing universal access panels without considering surface type can cause failures during pressure or water tests. Using purpose-built models for each application avoids rework, minimizes downtime, and maintains OSHA and building code compliance—keeping projects on schedule and budgets under control.

Maintain a Unified and Professional Appearance

When you use the right roof, floor, and wall access door, everything fits properly and looks seamless. Flush fittings, consistent finishes, and surface uniformity tie the space together, ensuring your project looks as solid as it performs.

Ready to find access panels built for every surface? Explore our full range of wall, ceiling, and floor access solutions designed for long-term performance, airtight sealing, and a unified finish across your projects.

How Do BA-UHF-G and BA-RFD Deliver Safety and Aesthetic Consistency?

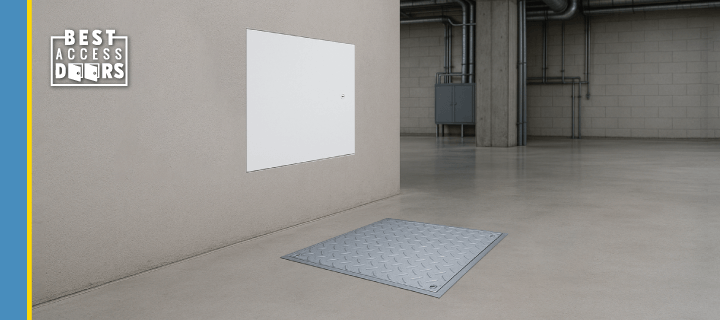

The BA-UHF-G and BA-RFD deliver safety and aesthetic consistency by combining performance built for each surface type while keeping everything looking consistent. Each one is made for its specific location: the BA-UHF-G for walls and ceilings, and the BA-RFD for floors.

But together, they help contractors and facility teams maintain a consistent finish across different surfaces without compromising safety or durability. It's a simple way to keep every part of the building working together seamlessly.

BA-UHF-G: Hidden Strength Behind a Seamless Finish

The BA-UHF-G Aesthetic Access Door with Hidden Flange and Gasket blends strength with a modern, minimal look. Its concealed flange sits flush with the surface, and the neoprene gasket seals out drafts and reduces airflow between rooms.

Built from durable 16-gauge steel and powder-coated for corrosion resistance, this hidden flange access panel installs easily without the mess of mud or plaster. It's ideal for wall or ceiling applications that must stay clean and airtight.

BA-RFD: Slip-Resistant Access for Demanding Floor Conditions

For floors, the BA-RFD Removable Diamond Plated Floor Hatch provides a durable, load-rated solution built to handle heavy foot traffic. This diamond-plated aluminum floor hatch ensures secure footing even in damp areas, while the non-hinged, removable design offers more room for inspections and tool transport.

With a reinforced frame that supports up to 150 pounds per square foot, this hatch combines reliability and safety without compromising aesthetics.

Choose access panels that work the way you need them to. Request a quote for ready-to-ship models or get custom access solutions designed for your size and finish requirements.

What Features Ensure Reliable Air and Water Sealing?

Reliable air and water sealing starts with the right combination of materials, gaskets, and precision-fit construction. Access doors and panels that use these features protect buildings from leaks, drafts, and early deterioration.

For contractors and facility engineers, these details separate a temporary solution from a long-lasting installation.

Perimeter Gasket To Keep the Seal Tight

High-quality gaskets are the first line of defense against air and water infiltration. The BA-UHF-G, for example, uses a neoprene perimeter gasket to create a tight seal between the frame and the panel. This design prevents unwanted airflow and helps maintain pressure balance in controlled environments.

In humid or conditioned spaces, a gasketed access panel also helps reduce condensation, protecting nearby equipment from moisture damage.

Precision Construction That Prevents Gaps

Reliable sealing also depends on how well the door and frame fit together. Panels with concealed flanges and smooth, flush installations eliminate uneven gaps where air or water could seep through. A tight, well-fitted frame—like the one used in the BA-UHF-G—improves overall durability and helps extend the system's lifespan.

Related blog: The Top 3 Watertight Access Doors for Architects Designing in Moisture-Prone Areas

Where Should You Use Hidden-Flange vs. Floor-Rated Access Doors?

You should use hidden-flange access doors for walls and ceilings where appearance and sealing matter most, and floor-rated access doors for heavy-use areas where strength and slip resistance are necessary.

Each type is built for a different purpose, and choosing the right one ensures safety, performance, and a consistent finish across every part of your building.

Using Hidden-Flange Access Doors for Walls and Ceilings

Hidden-flange models like the BA-UHF-G are made to blend into the surface, leaving a smooth, flush finish that fits perfectly with drywall or masonry. Thanks to their built-in gaskets, these panels keep interiors looking clean while maintaining airtight performance.

They're ideal for spaces where you want access without the hardware showing, like offices, hotels, or healthcare facilities.

Using Floor-Rated Access Doors for Load and Slip Resistance

Floor-rated options like the BA-RFD are all about strength and safety. The diamond-plated aluminum cover provides solid traction in damp or high-traffic areas, while its load-bearing frame supports up to 150 pounds per square foot.

The removable cover makes maintenance easy, giving crews clear access without tripping hazards or hinged obstructions.

How Can Contractors Simplify Mixed-Surface Specifications?

Contractors can simplify mixed-surface specifications by choosing access doors with consistent design standards, materials, and performance features across all surfaces.

Instead of sourcing different brands or models for walls, ceilings, and floors, standardizing with a single compatible product line helps streamline submittals, installation, and inspections.

Standardizing for Consistency and Compliance

Using access panels designed to work together across multiple applications ensures uniform finishes and simplified documentation. When each model follows the same performance benchmarks—like load rating, fire testing, or gasket sealing—it's easier to meet OSHA compliance and building code requirements.

This consistency also speeds up approvals by giving engineers, designers, and inspectors one reliable reference point.

Reducing Rework and Coordination Issues

Coordinating among trades becomes much smoother when everyone works with the same access panel standards. Installers can use identical framing details and mounting methods for different surfaces, which reduces layout conflicts and the need for remeasurement.

Fewer variations also mean fewer surprises—no last-minute adjustments, mismatched finishes, or delays waiting on replacement parts.

Related blog: Which Access Panel Specs Get Reused Across Multiple Commercial Projects?

Frequently Asked Questions About Multi-Surface Access Panels

1. Can one access panel be used for both walls and floors?

Not usually. Each surface has different requirements—floors need load-rated, slip-resistant panels, while walls and ceilings need lighter, gasketed options for airtight performance. Using one model everywhere can cause leaks, corrosion, or compliance issues.

2. What makes a hidden-flange access panel ideal for modern interiors?

A hidden flange access panel sits flush with the wall or ceiling, hiding edges and hardware for a smooth, seamless look. It's perfect for spaces that prioritize clean finishes and easy maintenance access.

3. Why are gaskets important in access doors and panels?

Gaskets prevent air and water infiltration, helping maintain comfort, energy efficiency, and surface uniformity. They're especially valuable in humidity-prone or temperature-controlled spaces, where protecting surrounding materials from moisture is necessary.

Conclusion

Matching the right access panel to each surface is about ensuring safety, durability, and consistent performance across your entire build. Roofs, walls, and floors all have different demands, and using multi-surface access doors that complement each other keeps every installation sealed, stable, and compliant.

When you choose universal access panels designed for their specific environments, you reduce rework, protect against leaks or corrosion, and maintain a unified finish from top to bottom. It's a smarter, safer way to design buildings that look great and perform reliably for years to come.

Need help choosing the right access panels for every surface? Our experts are here to help. Call +1-888-327-5471 or visit our Contact Us page to get personalized recommendations and support.

Share our story - the 2025 version is available

Feedback

Feedback