Why Choose a Corrosion-Resistant, Lightweight, and Insulated Access Door?

Posted by Best Access Doors on 13th Jul 2022

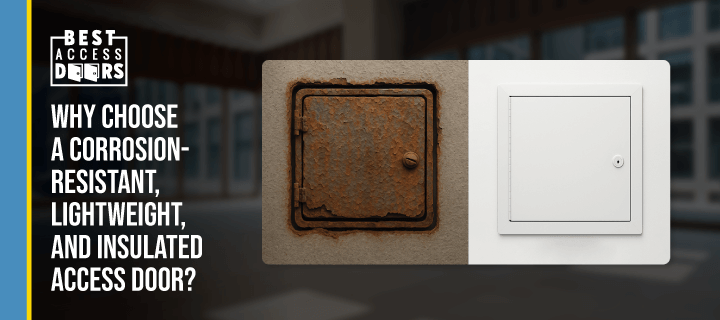

When energy loss, rust, and bulky installations start cutting into your bottom line, it's time to rethink the basics—starting with your access doors.

For property owners, contractors, and facility managers facing rising performance demands, corrosion-resistant, lightweight, and insulated access doors offer a more efficient alternative.

Besides being budget-friendly, they stand up to harsh weather conditions, are easier to install and operate, and help regulate indoor temperature.

Let's explore why weather resistance, lightweight design, and built-in insulation contribute to better performance in access doors and panels.

Corrosion Resistance

Weather-resistant access doors are a must-have for environments prone to rust. These include high-moisture areas such as basements, coastal regions, outdoors, or industries with chemical exposure.

Besides affecting aesthetics, corrosion can cause considerable damage to property and equipment. According to AMPP (formerly NACE International), corrosion costs the U.S. $2.5 trillion annually.

Think about the hidden pipes and electrical conduits behind an access panel. Rust in these areas can cause system failures, leading to expensive replacements or repairs.

Depending on the application, corrosion-resistant doors help prevent these issues. They're also typically made from durable materials such as stainless steel and aluminum.

In food processing environments or healthcare facilities, these doors are vital not only for durability but also to prevent bacterial buildup and maintain stringent hygiene standards.

Regardless of which material you choose, corrosion-resistant doors are essential to protecting commercial buildings and are an investment in the future of any business.

Lightweight Design

The weight of building materials directly impacts labor, logistics, and structural requirements.

For instance, installing a lightweight ceiling hatch made from aluminum is much easier than a heavy steel door. This translates to faster installation times.

Once installed, it's easy to hold the door open, which is helpful for technicians and maintenance staff doing inspections and repairs. There is also less strain on building infrastructure, reducing the cost of repairs over time.

But "lightweight" doesn't mean weak. Modern materials—like aluminum composites or engineered plastics—offer excellent strength, ensuring durability without the bulk.

Insulation

Insulated access doors are designed to regulate the thermal performance of buildings. They feature advanced core materials like rigid foam or mineral wool that create a thermal barrier.

This helps prevent drafts, reduces the wear and tear on your HVAC system, and minimizes the need for costly repairs.

By supporting overall insulation, these doors promote energy-efficient, loweringcosts and improving indoor comfort. Research shows that property owners can save up to 15% on energy costs by air sealing and adding insulation around attics and crawl spaces.

Factors To Consider for Insulated Access Doors

By considering the R-value, size, type of insulation, and price, you can ensure you're choosing the right door for your needs.

- R-Value: It measures thermal resistance and determines how well the door keeps heat in or out. The greater the R-value, the better insulated the door.

- Airtightness: A tight seal prevents air leakage, which can significantly negate insulation benefits. Look for quality gasketing like neoprene.

- Location and Environment: Consider if the door is for interior or exterior use. Exterior applications demand enhanced weather sealing, UV resistance, and corrosion resistance to withstand elements like extreme temperatures and moisture.

- Fire Rating: Fire-rated insulated doors are essential for certain applications to meet building codes and enhance safety.

Whether you are looking for increased efficiency, reduced energy costs, or a more aesthetically pleasing look for your building, lightweight access doors are a great option.

Got any other specialized requirements for your project? Browse our custom access solutions for unique sizes, materials, locking mechanisms, and finish options.

Benefits of Installing a Corrosion-Resistant, Lightweight, Insulated Access Door

- It keeps your property looking new and fresh for years.

- It prevents water and weather damage that can lead to costly repairs.

- It helps to maintain a moderate temperature throughout your building.

- It reduces the need for expensive repairs.

- It lessens the wear and tear on HVAC systems.

- Lowers your energy consumption, which cuts costs

- Easier to install than heavy steel doors

- One person can easily hold a lightweight door open, especially when installed in a large opening or a ceiling.

Our Recommendation: BA-PAL

The BA-PAL is a popular weather-resistant, lightweight, insulated access door for high-humidity areas and harsh environments.

With 1" fiberglass wool insulation and a neoprene gasket, BA-PAL reduces sound and air transfer between partitions. The robust all-aluminum construction allows its use in large wall or ceiling openings where corrosion and moisture are a concern.

Besides being lightweight and easy to install, BA-PAL features a flush-to-frame door for aesthetics and a key-operated cylinder for security.

Review the spec sheet for BA-PAL, and then contact us with your questions. Our short video lets you see it up close!

Conclusion

Choosing a corrosion-resistant, lightweight, and insulated access door helps your project stay on budget, meet code requirements, and deliver long-term value.

From energy-efficient inspection covers to lightweight ceiling hatches, the right choice ensures your builds stay smart, efficient, and future-ready.

Don't let overlooked components compromise your project's integrity and profitability. Join our Pro Club for priority support or call +1-888-327-5471 to speak to our team of experts today!

Share our story - the 2025 version is available

Feedback

Feedback