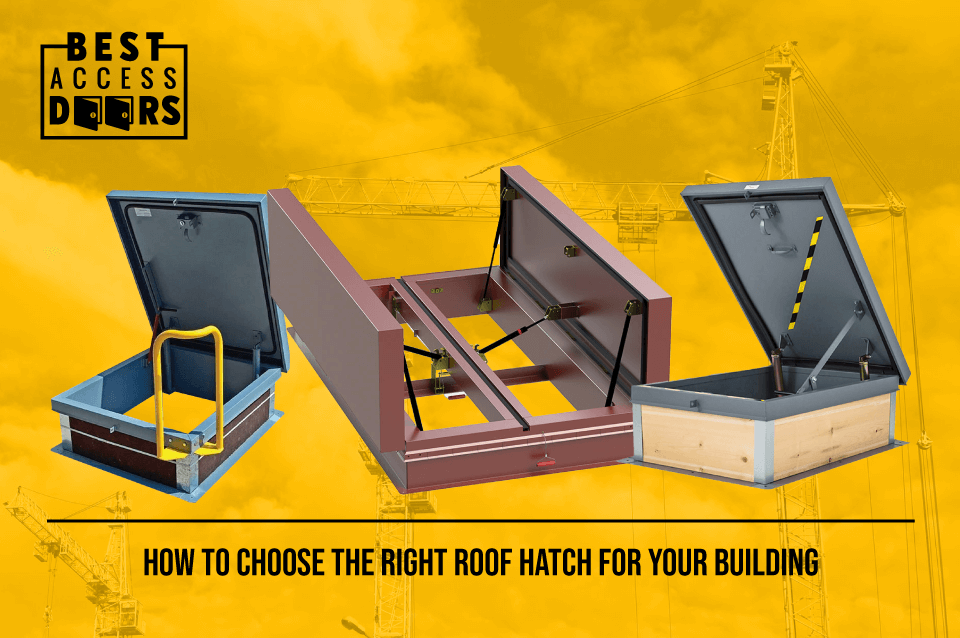

How to Choose the Right Roof Hatch for Your Building

Posted by Best Access Doors on 31st Aug 2017

If you find that your place of business requires you to go up on the roof frequently, you may be dragging ladders, leaning it on the building rooftop, and climbing up rain or shine. In commercial building spaces where you have this kind of situation, then it’s time for you to consider installing a roof hatch in your workplace.

Having A Roof Hatch Makes Access Easier

Roof hatches are horizontal doors that provide covered roof openings depending on building type and are accessed through an interior ladder, service stair, or ship stair.

Step #1: Determine the Purpose

Since there are various roof hatches on the market available for commercial building use, it is essential to determine first the purpose of your roof hatch to help you narrow down your choices.

Here are some factors that will help you to determine what type of roof hatches you need.

Is the Access Required for Personnel or Equipment?

The purpose of the roof hatch is one of the primary factors that need consideration because it will make a huge difference in which you choose.

Step #2: Determine the Size

If the hatch is for personnel access, then a small, single-cover roof hatch will be fine for you. You then need to specify the ladder access - whether a fixed, ship, or service stair.

If the person accessing the roof hatch will be carrying extensive tools or spare parts onto the roof for regular roof maintenance, then considering a large hatch will suit your needs.

Equipment access hatches have bigger sizes than the personnel access hatches and are typically double-cover models.

Most of the equipment hatches are custom manufactured based on the type and dimensions requirements. These measurements will determine the exact size of the hatch.

In customizing the equipment access hatch, the manufacturer will verify the hatch clear opening and hardware locations. And in some cases, custom hardware is required.

For example, a hatch installed in a hospital room with a Magnetic Resonance Imaging (MRI) machine needs non-magnetic hardware material.

Is It a Brand New Installation or Replacement for an Older Roof Hatch?

If there is already a hatch installed and cannot serve its purpose anymore, it might not be a big deal to get it back on track to become operational again.

Step #3: Determine the Type

Some available low-profile replacement hatches are ideal for retrofit applications. To avoid the need to replace the roofing material by simply capping over the existing hatch curb.

Once the old hatch cover is removed, mount the new one onto its existing hatch curb, and together with the flanged and gasket insulation design, you can ensure that you have a watertight roof hatch installation.

On What Type of Facility Will the Hatch Be Installed?

Your choice for the roof hatch will vary on the type of building.

For example, if your space is a bank or pharmacy, it requires you to have a high-security hatch that protects you from any unauthorized access in your space.

A high-security hatch with high-quality and heavier gauge material with several enhanced security design options. Some available features on a high-security roof hatch are:

- Gun ports

- Bulletproof view windows

- Deadlocks

Another instance of a specialized roof hatch is when you have a dark working environment, mainly industrial and manufacturing building structures.

Having a small transparent portion on roofing will allow daylight to shed light on these kinds of spaces. And there is a roof hatch that will serve this purpose.

Having a roof hatch with a polycarbonate dome cover design will allow natural daylight into the building, provide a more pleasant working environment, and help to reduce energy consumptions and costs.

Step #4: Choose the Material

Another main factor to consider is corrosive elements found in a chemical plant or buildings located in coastal areas where weather conditions can sometimes be extreme.

In buildings where corrosion is an issue, high corrosion resistance material is suitable in these types of facilities, such as aluminum or stainless roof hatches and copper roof hatches that provide an aesthetic look for a historical building structure.

Though stainless steel, aluminum, and copper roof hatches are more expensive than any other material.

What Should You Look For in a High-Quality Hatch?

The majority of roof hatches are made from galvanized steel, as they are the least expensive material. However, you can also specify customized hatches made from aluminum, stainless steel, and even copper.

Once you already decide on your material choice, there are four factors that you need to consider in choosing the proper hatch.

Step #5: Choose the Opening Mechanism

Is It Easy to Use?

Ease of use is one essential thing to consider when selecting a roof hatch.

It will help if you inspect the hatch that opens easily upward from inside, especially that this hatch is not often that a staff member will stand on the ladder or stairs to open the roof hatch. And when they do, usually with tools in their hands.

So it is better to have a hatch with a uniform opening operation to ensure a safe and easy opening and closing of your roof hatch.

Is There a Need for Mechanical Help in Lifting the Hatch?

Install compression springs or anything that helps counterbalance during its operation, especially if the cover is large and heavy.

The roof hatch needs to have an automatic open lock to hold the cover in the open position. It is a safety feature to avoid slam shut of the hatch cover anytime and mitigate hatch operation accidents.

Step #6: Select Insulation Options

Does It Help, or at Least Maintain, Energy Performance Levels in the Building?

Ensure that the hatch corners are fully welded and complete insulation both in cover and curb. Some manufactures offer insulation options to enhance thermal performance.

It needs to check if there is an overlap of the cover and if the gasket snugly fits into the roof hatch cover to ensure that the hatch is watertight and weathertight.

Step #7: Determine Safety Requirements

Does It Need Fall Protection Railings?

Fall protection railing is a must based on OSHA standards; you can turn to the experts to better understand how it will impact the installation of your roof hatch.

All of these guidelines will help you in choosing the proper roof hatch in your building.

Conclusion

Selecting the appropriate roof hatch for your building is crucial to ensure functionality, safety, and convenience. When making this decision, consider the BA-TRH Galvannealed Roof Hatch as a top choice and offers a range of benefits, including durability, weather resistance, and easy access to rooftops.

By choosing this high-quality roof hatch, you can enhance the overall efficiency and accessibility of your building. We offer a wide selection of access doors and panels, including the BA-TRH Galvannealed Roof Hatch. Make an informed decision and ensure the utmost satisfaction with your roof hatch choice. Contact us today!

Share our story - get our 2024 Catalog for FREE!